Photovoltaic System Installations

After the correct design is achieved, correct electrical and mechanical installations have to be made to insure efficiency and longevity of your system. Only seasoned electrical contractors who specialize in power system can deliver these type systems day in and day out, for any scenario or condition. Photovoltaic systems can not be installed using a monkey see, monkey do , training program or by simply attending a two week boot camp or educational program from entities who sometimes do not cover what they should. The systems produce electricity, sometimes as high as 600 vdc, dangerous stuff. Objectionable current issues can kill or cause fires. Additionally efficiency can only be provided if electrical theory, plus experience working with electricity, thru all kinds of different load and ambient temperature scenarios, exist.

Electrical License

There has been discussion as to whether an electrical license was necessary in order to be able to provide and install photovoltaic systems to the consumer. There is simple answer, YES!

Photovoltaic systems produce electricity and actually can be more dangerous than the electricity provided by your utility company. Some systems operate at close to 600 vdc so a complete understanding of electricity is critical!

Correct grounding of photovoltaic systems is extremely important for preventing electrocution. Due to the extreme conditions most connections are subjected to, extra attention in making sure there is enough pressure between surfaces is necessary. A complete and low impedance path must be maintained for proper operation of all overcurrent devices so that fault current can be dealt with quickly.

The understanding of electrical theory can go a long way in providing the knowledge necessary for consumer and technician safety and also for efficient installations. Voltage drop can create havoc for photovoltaic systems and their efficiency.

The licensing system in all states may not be perfect and some contractors are probably holding licenses which should not. However the application process for getting any trade license does require the proof of experience. This in itself benefits the end user and any type system which is installed.

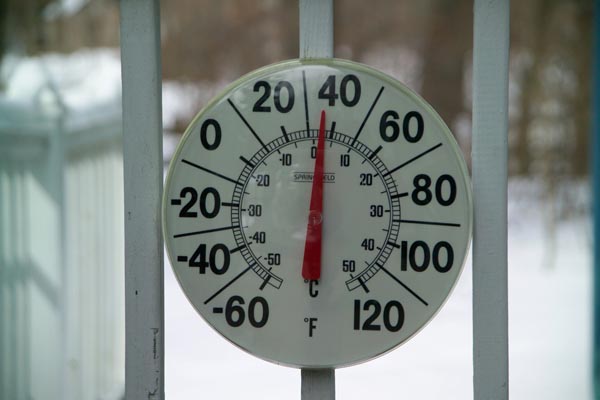

Temperature Considerations

Ambient temperatures combined with direct sunlight hitting a solar array will decrease the efficiency of the solar panels if adequate spacing for ventilation is not part of your design and then installation. This occurs due to additional resistance caused by the increased temperatures reducing the output voltage of the individual panels. The amount of spacing between the solar panels and roof structure should be calculated to offer the most ventilation while not creating a possible wind sail issue. Additionally correct voltage calculation are necessary for voltage output levels during cold conditons so that the correct equipment is used for the job.

Grounding and Shock Hazards

All equipment, enclosures, or conductive materials associated with the photovoltaic system must be bonded together. This provides possible fault currents a path back to the source and then to ground. Without effective grounding overcurrent devices would not trip fast enough to provide the intended safety.

Using seasoned electrical contractors with a good understanding of correct grounding is your best defense against touch voltage which can be very dangerous.

Connection of solar array racking can be tied to the grounding electrode of the structure only. A separate grounding electrode should not be installed for just the array or hardware used for installation of the array. Connection of the array and associated hardware to the structure grounding electrode conductor can provide some lighting protection if grounding electrode system is effective, less than 15 ohms of resistance.

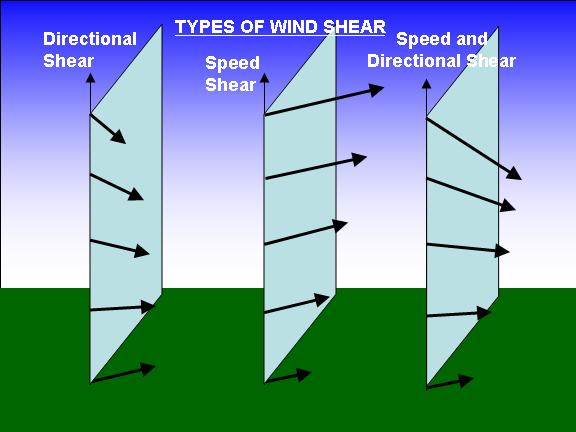

Wind Considerations

Although wind is a good source of energy for alternative power it is not a friend to solar arrays. Although it is necessary to provide some clearance between the solar panels and the roof structure, focus should also be on not creating a wind sail. Additionally a thorough inspection of the roof structure should be performed and the integrity of the roof verified before attaching any equipment associated with a photovoltaic array to it.

If the slope of the roof or structure surface creates the need for separation of the panels from the structure in order to obtain the correct azimuth of the sun, well thought out bracing for array hardware will be necessary. An inspection of the array hardware should be inspected for tightened fasteners.

Voltage Drop Considerations

Due to lower voltage outputs of some arrays consideration should be given to the size of conductors between the array and inverter equipment. This is a mistake made often and it is a efficiency killer. Voltage and current specifications of solar panels as well as certain code requirements determine the conductor size necessary to insure efficiency and safety.

Ground clips like shown above and similar fasteners are used to eliminate touch voltages of electrical devices and equipment.

Overcurrent devices as shown above do not protect personnel nor expensive equipment if effective grounding is not implemented.

Loss Factors

There are numerous loss factors that can affect real system performance including component performance, wire losses, soiling of array, module degradation, module mismatch, system uptime and reliability, manufacturer production tolerance, and system design factors such as tilt, orientation, shading, and air flow.

E & W Electrical, LLC

515 Meadowland Drive

Suite 100

Hillsborough, NC 27278

919-245-0200 (office)

919-245-0202 (facsimile)

888-919-5210 (toll free)

copyright 2010 E & W Electrical ** All rights reserved